Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Why the Start of the Year Is Best for an LEV System Review

The New Year marks a vital opportunity for engineering and manufacturing businesses to prioritise operational safety and efficiency. Performing a detailed Local Exhaust Ventilation (LEV) system review now is not just a compliance exercise; it protects employees, prevents costly disruptions, and ensures full workplace safety compliance. Ventilation systems can be affected by winter conditions, with filters clogging, ductwork accumulating debris, and extraction arms misaligning. Addressing these issues through preventative maintenance early preserves equipment performance and air quality. Beyond equipment, a well-maintained LEV system safeguards staff health, reduces exposure to harmful particles, and demonstrates a proactive commitment to workplace safety. Beginning the year with a comprehensive review ensures operational continuity, a safe working environment, and a strong foundation for a productive 2026.

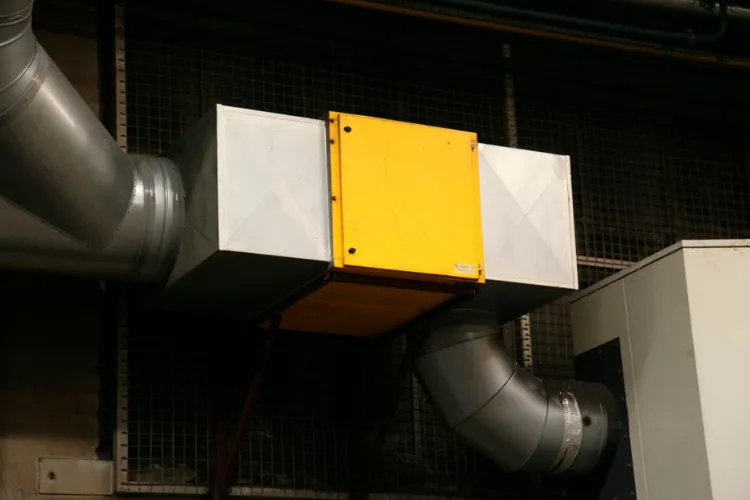

Alt text: A safety engineer carefully inspecting an LEV system, showing commitment to staff health and protecting workers from hazardous airborne contaminants.

Why a New Year LEV System Review Matters

1. Maintain Compliance Confidence

Compliance with regulations such as COSHH is non-negotiable for manufacturing and engineering businesses. Conducting an LEV system review at the start of the year ensures your systems are fully audit-ready, reducing the risk of fines and operational interruptions. A timely review demonstrates accountability and reassures both employees and regulatory bodies that workplace safety is a top priority.

2. Preventative Maintenance Protects Systems

Filters, ductwork, and extraction arms face constant wear and tear. Without timely intervention, small issues can escalate into significant operational disruptions. Scheduling preventative maintenance during the New Year allows businesses to detect problems early, maintain system efficiency, and prevent unexpected downtime, ultimately protecting staff and supporting consistent production performance.

Alt text: Technician replacing and testing LEV filters during preventative maintenance to maintain clean air and ensure the system supports a healthy workplace environment.

3. Improve Workplace Safety and Well-being

Well-functioning LEV systems reduce exposure to airborne particles, ensuring a healthier working environment. Staff notice when their employer prioritises safety, which builds trust, improves engagement, and promotes a positive organisational culture. Healthy employees are more productive, experience fewer absences, and contribute to a more efficient workflow.

4. Optimise System Performance for the Year Ahead

A thorough review highlights areas where airflow efficiency can be improved, ensuring that extraction and filtration systems operate at peak performance. Optimised LEV systems reduce energy consumption, prevent overheating, and maintain consistent air quality, helping your workforce perform in a safer, healthier environment.

4. Plan Upgrades Before Production Peaks

Reviews often uncover ageing or underperforming components. Identifying these early allows businesses to plan upgrades or replacements before the busy season begins. Proactive upgrades not only prevent last-minute disruptions but also extend the lifespan of your equipment, making operations smoother and more cost-effective throughout the year.

Planning Upgrades and Operational Efficiency

A comprehensive review often reveals equipment that is outdated, underperforming, or nearing the end of its lifecycle. Addressing these areas now allows businesses to plan timely upgrades, source genuine spare parts, and implement solutions that maintain optimal airflow and performance. By acting early, companies reduce the risk of unplanned downtime, avoid costly last-minute replacements, and ensure long-term compliance with workplace safety standards.

How Experts Support Your LEV System Review

Professional teams bring specialised knowledge and ensure that reviews are both thorough and actionable. Services include:

Full LEV system inspections with COSHH-compliant documentation

Filter replacements, ductwork alignment, and operational checks

Recommendations for upgrades or modernisation of existing systems

Supply of genuine spare parts for reliable long-term performance

Ongoing guidance for workplace safety compliance and employee training

Learn more about official UK guidance on LEV effectiveness and compliance at the Health & Safety Executive’s LEV resource page the definitive standard for protecting workers from airborne hazards.

Refer to this guidance when planning your review to ensure your process aligns with recognised best practice.

Key Benefits You’ll Gain

1. Ensure Workplace Safety Compliance

A timely review guarantees adherence to regulations, reduces the risk of fines, and ensures your business remains fully prepared for inspections. Regular documentation and system checks reinforce credibility and demonstrate a proactive approach to staff safety.

2. Reduce Operational Risks

Detecting and resolving minor issues early prevents unexpected equipment failures. A proactive LEV system review minimises hazards, avoids costly downtime, and safeguards both employees and production schedules.

3. Maintain Clean Air

Optimised ventilation systems improve air quality throughout your facility, lowering exposure to dust and harmful particles. Healthy air contributes to staff well-being, reduces sick days, and creates a more productive workplace environment.

4. Cost-Efficient Maintenance

Addressing minor faults through preventative maintenance reduces the likelihood of expensive emergency repairs. Regular upkeep protects your investment, extends the life of equipment, and ensures consistent operational efficiency year-round.

5. Build Staff Confidence

A visible commitment to safety fosters trust, loyalty, and engagement. Employees are reassured that management values their health and well-being, which contributes to stronger morale and a safer, more focused workforce.

Alt text: Employer reviewing full LEV test reports with team members, reinforcing commitment to safe working conditions and peace of mind.

Final Thoughts

A comprehensive LEV system review is more than compliance; it’s a strategic investment in your team, operations, and long-term success. By acting now, you identify hidden issues, implement preventative maintenance, and ensure consistent air quality, protecting employees and minimising costly disruptions. Professional inspections combined with timely upgrades strengthen workplace safety compliance, foster trust among staff, and guarantee smooth, uninterrupted operations. This proactive approach sends a clear message: your organisation values employee welfare and operational excellence. Make the first step towards a safer, more productive 2026 and transform your LEV systems into a foundation of efficiency, protection, and peace of mind.

Don’t wait for a safety issue to strike.

Protect your team and ensure full compliance now. Book your LEV system review with Workplace Safety Management Today and secure a safer, worry-free workplace.

Frequently Asked Questions (FAQs)

1. How often should an LEV system review be conducted?

A comprehensive review should be carried out at least once a year, with more frequent checks for high-usage or high-risk environments to ensure ongoing safety and compliance.

2. What key benefits does a New Year LEV review provide?

It guarantees regulatory compliance, identifies hidden system issues early, maintains clean air quality, and ensures uninterrupted production throughout the year.

3. Can preventative maintenance actually save costs?

Yes. Timely maintenance prevents unexpected breakdowns, reduces emergency repair expenses, and extends the lifespan of your LEV equipment.

4. Is professional expertise necessary for an LEV system review?

Absolutely. Certified experts deliver accurate inspections, COSHH-compliant documentation, and actionable guidance for system optimisation and staff safety.

5. How does an LEV system review enhance workplace safety?

It identifies hazards, confirms the system is fully functional, and ensures employees are protected from harmful airborne contaminants.

Why the Start of the Year Is Best for an LEV System Review

The New Year marks a vital opportunity for engineering and manufacturing businesses to prioritise operational safety and efficiency. Performing a detailed Local Exhaust Ventilation (LEV) system review now is not just a compliance exercise; it protects employees, prevents costly disruptions, and ensures full workplace safety compliance. Ventilation systems can be affected by winter conditions, with filters clogging, ductwork accumulating debris, and extraction arms misaligning. Addressing these issues through preventative maintenance early preserves equipment performance and air quality. Beyond equipment, a well-maintained LEV system safeguards staff health, reduces exposure to harmful particles, and demonstrates a proactive commitment to workplace safety. Beginning the year with a comprehensive review ensures operational continuity, a safe working environment, and a strong foundation for a productive 2026.

Alt text: A safety engineer carefully inspecting an LEV system, showing commitment to staff health and protecting workers from hazardous airborne contaminants.

Why a New Year LEV System Review Matters

1. Maintain Compliance Confidence

Compliance with regulations such as COSHH is non-negotiable for manufacturing and engineering businesses. Conducting an LEV system review at the start of the year ensures your systems are fully audit-ready, reducing the risk of fines and operational interruptions. A timely review demonstrates accountability and reassures both employees and regulatory bodies that workplace safety is a top priority.

2. Preventative Maintenance Protects Systems

Filters, ductwork, and extraction arms face constant wear and tear. Without timely intervention, small issues can escalate into significant operational disruptions. Scheduling preventative maintenance during the New Year allows businesses to detect problems early, maintain system efficiency, and prevent unexpected downtime, ultimately protecting staff and supporting consistent production performance.

Alt text: Technician replacing and testing LEV filters during preventative maintenance to maintain clean air and ensure the system supports a healthy workplace environment.

3. Improve Workplace Safety and Well-being

Well-functioning LEV systems reduce exposure to airborne particles, ensuring a healthier working environment. Staff notice when their employer prioritises safety, which builds trust, improves engagement, and promotes a positive organisational culture. Healthy employees are more productive, experience fewer absences, and contribute to a more efficient workflow.

4. Optimise System Performance for the Year Ahead

A thorough review highlights areas where airflow efficiency can be improved, ensuring that extraction and filtration systems operate at peak performance. Optimised LEV systems reduce energy consumption, prevent overheating, and maintain consistent air quality, helping your workforce perform in a safer, healthier environment.

4. Plan Upgrades Before Production Peaks

Reviews often uncover ageing or underperforming components. Identifying these early allows businesses to plan upgrades or replacements before the busy season begins. Proactive upgrades not only prevent last-minute disruptions but also extend the lifespan of your equipment, making operations smoother and more cost-effective throughout the year.

Planning Upgrades and Operational Efficiency

A comprehensive review often reveals equipment that is outdated, underperforming, or nearing the end of its lifecycle. Addressing these areas now allows businesses to plan timely upgrades, source genuine spare parts, and implement solutions that maintain optimal airflow and performance. By acting early, companies reduce the risk of unplanned downtime, avoid costly last-minute replacements, and ensure long-term compliance with workplace safety standards.

How Experts Support Your LEV System Review

Professional teams bring specialised knowledge and ensure that reviews are both thorough and actionable. Services include:

Full LEV system inspections with COSHH-compliant documentation

Filter replacements, ductwork alignment, and operational checks

Recommendations for upgrades or modernisation of existing systems

Supply of genuine spare parts for reliable long-term performance

Ongoing guidance for workplace safety compliance and employee training

Learn more about official UK guidance on LEV effectiveness and compliance at the Health & Safety Executive’s LEV resource page the definitive standard for protecting workers from airborne hazards.

Refer to this guidance when planning your review to ensure your process aligns with recognised best practice.

Key Benefits You’ll Gain

1. Ensure Workplace Safety Compliance

A timely review guarantees adherence to regulations, reduces the risk of fines, and ensures your business remains fully prepared for inspections. Regular documentation and system checks reinforce credibility and demonstrate a proactive approach to staff safety.

2. Reduce Operational Risks

Detecting and resolving minor issues early prevents unexpected equipment failures. A proactive LEV system review minimises hazards, avoids costly downtime, and safeguards both employees and production schedules.

3. Maintain Clean Air

Optimised ventilation systems improve air quality throughout your facility, lowering exposure to dust and harmful particles. Healthy air contributes to staff well-being, reduces sick days, and creates a more productive workplace environment.

4. Cost-Efficient Maintenance

Addressing minor faults through preventative maintenance reduces the likelihood of expensive emergency repairs. Regular upkeep protects your investment, extends the life of equipment, and ensures consistent operational efficiency year-round.

5. Build Staff Confidence

A visible commitment to safety fosters trust, loyalty, and engagement. Employees are reassured that management values their health and well-being, which contributes to stronger morale and a safer, more focused workforce.

Alt text: Employer reviewing full LEV test reports with team members, reinforcing commitment to safe working conditions and peace of mind.

Final Thoughts

A comprehensive LEV system review is more than compliance; it’s a strategic investment in your team, operations, and long-term success. By acting now, you identify hidden issues, implement preventative maintenance, and ensure consistent air quality, protecting employees and minimising costly disruptions. Professional inspections combined with timely upgrades strengthen workplace safety compliance, foster trust among staff, and guarantee smooth, uninterrupted operations. This proactive approach sends a clear message: your organisation values employee welfare and operational excellence. Make the first step towards a safer, more productive 2026 and transform your LEV systems into a foundation of efficiency, protection, and peace of mind.

Don’t wait for a safety issue to strike.

Protect your team and ensure full compliance now. Book your LEV system review with Workplace Safety Management Today and secure a safer, worry-free workplace.

Frequently Asked Questions (FAQs)

1. How often should an LEV system review be conducted?

A comprehensive review should be carried out at least once a year, with more frequent checks for high-usage or high-risk environments to ensure ongoing safety and compliance.

2. What key benefits does a New Year LEV review provide?

It guarantees regulatory compliance, identifies hidden system issues early, maintains clean air quality, and ensures uninterrupted production throughout the year.

3. Can preventative maintenance actually save costs?

Yes. Timely maintenance prevents unexpected breakdowns, reduces emergency repair expenses, and extends the lifespan of your LEV equipment.

4. Is professional expertise necessary for an LEV system review?

Absolutely. Certified experts deliver accurate inspections, COSHH-compliant documentation, and actionable guidance for system optimisation and staff safety.

5. How does an LEV system review enhance workplace safety?

It identifies hazards, confirms the system is fully functional, and ensures employees are protected from harmful airborne contaminants.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Workplace Safety Management Ltd

Unit 1 Garden Court

Gee Road

Coalville

Leicestershire

LE67 4NB

Email: [email protected]

COMPANY INFO

CUSTOMER INFO

2025 Workplace Safety Management & Products