FlexHood

FlexHood is a modular extraction hood especially suitable for robotic welding applications.

Features

Suitable for industrial processes, such as (manual or robotic) welding, grinding and cutting.

Functional design, freestanding unit.

Effective extraction, thanks to rim extraction.

FlexHood - extraction hoods tailored to your needs

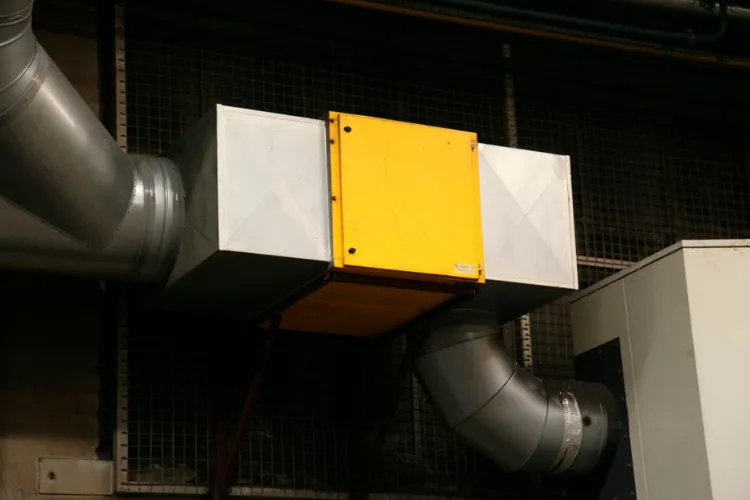

The FlexHood extraction hood is developed to cover a specific welding area, such as a robotic installation. When source extraction is impossible – for example due to the fact that welding robots move on a rail system - extraction hoods are an effective way to extract welding fumes near the actual process. It reduces the amount of fumes, small particles, fine dust, but also mist and aerosols in the workshop atmosphere.

Safety first

FlexHood is designed to protect welders, personnel in working areas, your working equipment and the facility. The deflection plates in the hood control the airflow and reduce the risk of sparks reaching the filter. Welding strips protect people working nearby from the welding light and equipment against spark and spatter.

Breakthrough in logistics

Traditional extraction hoods are often bulky and difficult to transport and maneuver inside a factory. The FlexHood is a breakthrough when it comes to logistical handling of an extraction hood. It comes in easy-to-handle modular parts and can easily be put together on site.

Robotic installations

FlexHood is often used to cover a robotic welding machine. The rising welding fumes are intercepted and extracted straight away via the rim extraction system in the main profiles of the roof.

Features

Modular concept

Innovative design

Efficient fume extraction

Easy to install and maintain

Safe, thanks to its integrated spark arrester