Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Why COSHH LEV Servicing is Vital for UK Workplaces: Real Stories, Legalities, and Lasting Benefits

Many UK-based engineering firms face a problem that often goes unnoticed: the air their teams breathe every day isn’t as clean as it should be. Local Exhaust Ventilation (LEV) systems and proper COSHH LEV servicing are crucial, yet without regular maintenance, staff are at risk. Poor air quality isn’t just a health concern, but it’s also a legal issue under the COSHH (Control of Substances Hazardous to Health) Regulations 2002.

That’s where Workplace Safety Management comes in. Our experts examine and test your systems thoroughly, protecting employees from fumes, dust, and airborne contaminants. The result? A workplace that is safe, compliant, and more productive, giving your team and your business confidence.

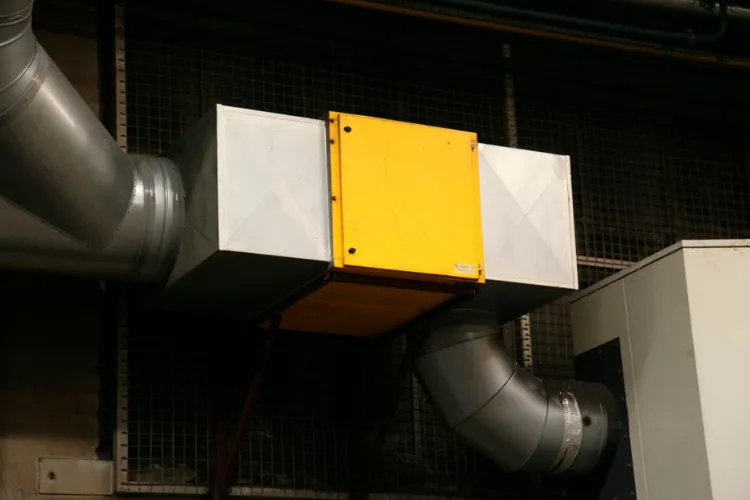

Alt Text: “Engineer checking ventilation equipment in a workshop to ensure clean and safe air for staff.

The Risk: What’s at Stake Without Regular COSHH LEV Servicing?

Legal Risk: Under UK law (COSHH Regulations 2002), employers must control employee exposure to hazardous substances. LEV systems should be examined and tested at least every 12 months.

Health Hazards: Poorly maintained LEVs can expose staff to fumes, dust, and airborne contaminants, leading to respiratory issues, skin conditions, and serious long-term illnesses.

Operational Downtime: Faulty systems can fail, causing unplanned downtime, expensive repairs, and lost productivity.

Reputation Damage: Failing an HSE (Health & Safety Executive) inspection may result in fines, enforcement action, and reputational harm.

Don’t wait for a problem to become a crisis. Secure your COSHH LEV inspection today and protect your team immediately!

The Legalities: What the Law Says

The COSHH Regulations require employers to prevent or adequately control exposure to hazardous substances. This includes:

Installing effective LEV systems.

Ensuring systems are regularly maintained and tested by competent professionals.

Keeping records of all servicing and tests.

Non-compliance can result in heavy fines, legal action, or even the closure of businesses. The HSE actively inspects engineering and manufacturing sites in order to make sure your company is prepared. Don’t let your company be caught out.

Stay on the right side of the law, book your LEV servicing now, and avoid costly fines!

The Benefits: Why Investing in COSHH LEV Servicing Pays Off

Protect Your Team: Healthy employees are more productive, engaged, and loyal.

Reduce Costs: Preventative maintenance avoids costly emergency repairs and extends equipment life.

Boost Compliance: Pass HSE inspections confidently, knowing your documentation and systems are up-to-date.

Peace of Mind: Focus on your core business, knowing your legal and ethical responsibilities are covered.

Ready to invest in your team’s health and your business’s future?

Secure your spot for a COSHH LEV inspection. Get in touch today!

Alt Text: “Team of workers in a workshop looking happy and focused while machinery operates smoothly in the background.”

To see the impact of regular COSHH LEV servicing, consider these real-life examples from UK workplaces

Real UK Case Stories: The Good, The Bad, and The Avoidable

Good News: A Success Story

A Midlands-based engineering firm partnered with us for regular COSHH LEV servicing. During a routine inspection, our engineers identified a minor airflow issue in one extraction arm. The fix was quick and inexpensive, and when the HSE visited, the company’s records and system performance were exemplary, allowing the team to continue working safely and confidently.

Be proactive like this company, reserve your COSHH LEV check now, and stay ahead of potential hazards!

Bad News: A Lesson Learned

A manufacturing plant in the North West neglected LEV servicing for over two years. When the HSE conducted a surprise inspection, multiple extraction points were not functioning, and no up-to-date service records were available. The company received a Prohibition Notice, halting production until the issues were resolved. The downtime cost tens of thousands in lost revenue, not to mention reputational damage and staff anxiety.

Don’t let this be your story. Your staff deserve safe air. Email us for a COSHH LEV check immediately!

Take Action: Protect Your People, Your Business, and Your Reputation

Whether you need to upgrade ventilation equipment, arrange a one-off COSHH test, or set up a regular maintenance plan, we’re here to help. With over 30 years of experience and a commitment to keeping UK workplaces safe and compliant, Workplace Safety Management is your trusted partner for LEV and COSHH compliance.

Ready to act now? Contact us today or call 0116 2742 336 to secure your workplace safety plan!

Act now, schedule your COSHH LEV servicing and upgrade your ventilation system before a hidden hazard puts your team and business at risk!

Why COSHH LEV Servicing is Vital for UK Workplaces: Real Stories, Legalities, and Lasting Benefits

Many UK-based engineering firms face a problem that often goes unnoticed: the air their teams breathe every day isn’t as clean as it should be. Local Exhaust Ventilation (LEV) systems and proper COSHH LEV servicing are crucial, yet without regular maintenance, staff are at risk. Poor air quality isn’t just a health concern, but it’s also a legal issue under the COSHH (Control of Substances Hazardous to Health) Regulations 2002.

That’s where Workplace Safety Management comes in. Our experts examine and test your systems thoroughly, protecting employees from fumes, dust, and airborne contaminants. The result? A workplace that is safe, compliant, and more productive, giving your team and your business confidence.

Alt Text: “Engineer checking ventilation equipment in a workshop to ensure clean and safe air for staff.

The Risk: What’s at Stake Without Regular COSHH LEV Servicing?

Legal Risk: Under UK law (COSHH Regulations 2002), employers must control employee exposure to hazardous substances. LEV systems should be examined and tested at least every 12 months.

Health Hazards: Poorly maintained LEVs can expose staff to fumes, dust, and airborne contaminants, leading to respiratory issues, skin conditions, and serious long-term illnesses.

Operational Downtime: Faulty systems can fail, causing unplanned downtime, expensive repairs, and lost productivity.

Reputation Damage: Failing an HSE (Health & Safety Executive) inspection may result in fines, enforcement action, and reputational harm.

Don’t wait for a problem to become a crisis. Secure your COSHH LEV inspection today and protect your team immediately!

The Legalities: What the Law Says

The COSHH Regulations require employers to prevent or adequately control exposure to hazardous substances. This includes:

Installing effective LEV systems.

Ensuring systems are regularly maintained and tested by competent professionals.

Keeping records of all servicing and tests.

Non-compliance can result in heavy fines, legal action, or even the closure of businesses. The HSE actively inspects engineering and manufacturing sites in order to make sure your company is prepared. Don’t let your company be caught out.

Stay on the right side of the law, book your LEV servicing now, and avoid costly fines!

The Benefits: Why Investing in COSHH LEV Servicing Pays Off

Protect Your Team: Healthy employees are more productive, engaged, and loyal.

Reduce Costs: Preventative maintenance avoids costly emergency repairs and extends equipment life.

Boost Compliance: Pass HSE inspections confidently, knowing your documentation and systems are up-to-date.

Peace of Mind: Focus on your core business, knowing your legal and ethical responsibilities are covered.

Ready to invest in your team’s health and your business’s future?

Secure your spot for a COSHH LEV inspection. Get in touch today!

Alt Text: “Team of workers in a workshop looking happy and focused while machinery operates smoothly in the background.”

To see the impact of regular COSHH LEV servicing, consider these real-life examples from UK workplaces

Real UK Case Stories: The Good, The Bad, and The Avoidable

Good News: A Success Story

A Midlands-based engineering firm partnered with us for regular COSHH LEV servicing. During a routine inspection, our engineers identified a minor airflow issue in one extraction arm. The fix was quick and inexpensive, and when the HSE visited, the company’s records and system performance were exemplary, allowing the team to continue working safely and confidently.

Be proactive like this company, reserve your COSHH LEV check now, and stay ahead of potential hazards!

Bad News: A Lesson Learned

A manufacturing plant in the North West neglected LEV servicing for over two years. When the HSE conducted a surprise inspection, multiple extraction points were not functioning, and no up-to-date service records were available. The company received a Prohibition Notice, halting production until the issues were resolved. The downtime cost tens of thousands in lost revenue, not to mention reputational damage and staff anxiety.

Don’t let this be your story. Your staff deserve safe air. Email us for a COSHH LEV check immediately!

Take Action: Protect Your People, Your Business, and Your Reputation

Whether you need to upgrade ventilation equipment, arrange a one-off COSHH test, or set up a regular maintenance plan, we’re here to help. With over 30 years of experience and a commitment to keeping UK workplaces safe and compliant, Workplace Safety Management is your trusted partner for LEV and COSHH compliance.

Ready to act now? Contact us today or call 0116 2742 336 to secure your workplace safety plan!

Act now, schedule your COSHH LEV servicing and upgrade your ventilation system before a hidden hazard puts your team and business at risk!

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Workplace Safety Management Ltd

Unit 1 Garden Court

Gee Road

Coalville

Leicestershire

LE67 4NB

Email: [email protected]

COMPANY INFO

CUSTOMER INFO

2025 Workplace Safety Management & Products