Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Why Are December and January Ideal for Workshop Air Quality Checks?

For many engineering workshops, fabrication shops, and small manufacturing businesses, December and early January bring a natural slowdown. Between Christmas shutdowns, reduced shifts, and planning for the year ahead, it’s one of the few times you can step back from day-to-day production.

This period is also the perfect opportunity to focus on workshop air quality, an area that often gets overlooked during busy operational months. Ensuring proper air quality not only protects your team’s health but also helps maintain equipment efficiency and compliance. By prioritising workshop air quality during the festive period, you can start the new year safe, productive, and fully compliant.

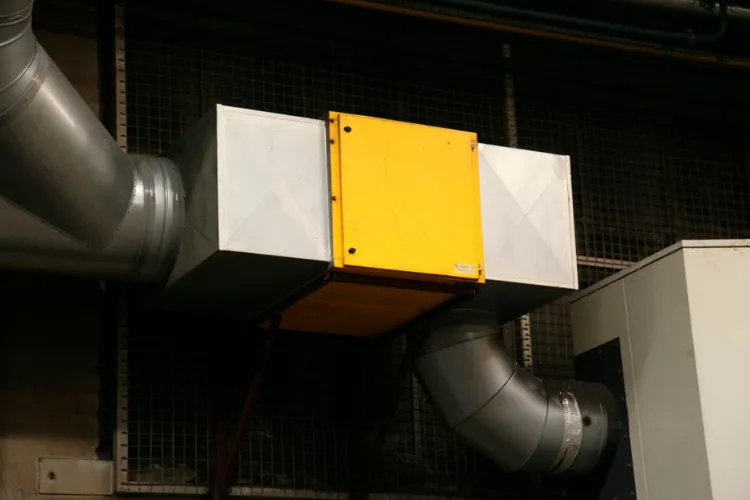

Alt text: Workshop air quality inspection during festive shutdown

Reduced Production Pressure

During the festive period, most workshops experience fewer active jobs. This reduction in day-to-day operations makes it easier to schedule inspections and maintenance without disrupting output.

Lower Staffing Levels

With some staff on leave for the holidays, coordinating maintenance becomes simpler. Fewer people on-site reduces interruptions and allows the team conducting checks to work efficiently. This period also provides an ideal opportunity to perform thorough inspections of ventilation systems, equipment, and workspaces without affecting day-to-day operations.

By addressing maintenance now, businesses can identify and fix potential issues before production ramps up, minimising the risk of downtime or safety hazards. Additionally, conducting maintenance during quieter periods ensures that when the full team returns, the workshop is fully optimised, safe, and ready for a productive start to the new year.

Planned Shutdowns

Many workshops have already scheduled partial or full shutdowns over Christmas and the New Year. This planned downtime is the perfect opportunity to take systems offline safely and perform thorough maintenance. With production paused, maintenance teams can conduct detailed inspections, clean hard-to-reach areas, and test system efficiency without interrupting operations. Taking advantage of this window helps prevent unexpected breakdowns, ensures equipment reliability, and sets the stage for a smooth, productive start to the new year.

Year-End Compliance

Completing LEV inspections and air quality checks before the start of the new year ensures that your workshop is fully compliant with COSHH regulations and safety standards from day one. It also allows any necessary repairs, upgrades, or adjustments to be carried out without disrupting normal operations. Early inspections help prevent potential safety risks, reduce the likelihood of regulatory non-compliance, and maintain a consistently healthy working environment.

Hidden Build-Up from the Year

Throughout the year, your workshop’s LEV systems work hard to capture welding fumes, grinding dust, paint overspray, wood dust, and other airborne contaminants. Over time, this can lead to:

Filters becoming clogged

Dust and debris are accumulating in the ductwork

Hoods and extraction arms are being knocked out of position

Gradual drops in performance that go unnoticed during daily operations

By December, many systems are overdue for a proper inspection and service. This hidden build-up can reduce airflow, compromise workshop air quality, and even pose safety risks if not addressed. Performing maintenance during the festive shutdown ensures systems are fully operational for the year ahead.

Improved Safety and Efficiency

Performing maintenance during these months reduces the risk of poor air quality-related hazards, such as fire or respiratory issues, and ensures that equipment operates at peak efficiency for the year ahead.

Foundation for a Productive Year

Addressing workshop air quality at this time sets the tone for a healthy, safe, and productive start to the new year, protecting staff, equipment, and overall operational efficiency. Ensuring clean, well-ventilated air reduces the risk of respiratory issues and fatigue, keeping your team alert and focused. It also helps prevent dust and airborne contaminants from settling on machinery and work surfaces, prolonging the lifespan of equipment and maintaining consistent product quality. By prioritising air quality early, businesses demonstrate a proactive commitment to safety and operational excellence, creating a positive work environment that supports both employee wellbeing and long-term performance.

Alt text: Engineers checking workshop air quality in December and January

Key Checks to Schedule During Christmas and New Year

To maintain optimal workshop air quality, schedule these critical tasks during your festive shutdown:

COSHH and LEV Examination and Testing

Ensure your LEV systems are examined and tested in line with COSHH requirements (at least every 14 months). December and January are ideal months to complete these inspections, ensuring full compliance for the new year.

Filter and Component Replacement

Replace worn filters, seals, and other consumable parts. Using genuine spare parts helps maintain performance and protects your investment in the system.

Cleaning and Ductwork Inspection

Remove dust and debris from ducting, hoods, and extraction points. Clean ductwork improves airflow, reduces fire risks, and enhances overall workshop air quality.

Performance Checks and Adjustments

Verify that extraction arms, hoods, and capture points are correctly positioned and delivering the right airflow at the point of use. Even minor misalignments can significantly reduce workshop air quality.

How Workplace Safety Management Can Help

At Workplace Safety Management, we support workshops and small engineering businesses across the UK with:

Planned festive shutdown maintenance for LEV systems

Replacement and upgrade of older or underperforming equipment

Supply of spare parts to keep systems reliable

COSHH-compliant LEV testing and documentation

Advice on improving workshop air quality for the year ahead

We understand that downtime is precious. That’s why we schedule our work around your shutdown dates, ensuring everything is ready for a safe, compliant, and productive start to the new year.

Making Clean Air Part of Your New Year's Plan

As you set targets for the year ahead and higher output, new contracts, and better efficiency and don’t forget the foundation that supports it all: a safe, healthy working environment. Using the quieter weeks around Christmas and New Year to service, test, and, if necessary, upgrade your LEV systems is an investment in your team, your equipment, and long-term productivity. High-quality workshop air quality improves performance, reduces sick days, and ensures compliance with safety regulations.

Conclusion: Start the Year with Cleaner Air

Investing in workshop air quality during the festive shutdown sets the tone for a safe, productive, and efficient year. By prioritising LEV system maintenance, filter replacements, cleaning, and testing in December and January, you protect your team, improve operational efficiency, and ensure full compliance with safety regulations. Taking the time now also reduces the risk of unexpected downtime, costly repairs, and health-related issues later in the year. Clean, well-maintained air systems not only safeguard your workforce but also enhance equipment longevity, maintain consistent performance, and create a more comfortable working environment for everyone on site.

Call Workplace Safety Management or book online to secure your slot before the festive period ends. Your team and your productivity deserve it.

FAQs

1. Why focus on workshop air quality in December and January?

These months are ideal due to quieter operations, planned shutdowns, and easier maintenance scheduling.

2. What maintenance should be done for workshop air quality?

LEV system checks, filter replacements, duct cleaning, and performance adjustments.

3. How often should LEV systems be tested?

At least every 14 months, or during scheduled shutdowns for optimal air quality.

4. What are the benefits of checking air quality during the festive period?

Improved safety, compliance, equipment efficiency, and a healthier working environment.

5. Can workshop air quality impact productivity?

Yes, poor air quality can reduce efficiency, increase health risks, and cause equipment issues.

Why Are December and January Ideal for Workshop Air Quality Checks?

For many engineering workshops, fabrication shops, and small manufacturing businesses, December and early January bring a natural slowdown. Between Christmas shutdowns, reduced shifts, and planning for the year ahead, it’s one of the few times you can step back from day-to-day production.

This period is also the perfect opportunity to focus on workshop air quality, an area that often gets overlooked during busy operational months. Ensuring proper air quality not only protects your team’s health but also helps maintain equipment efficiency and compliance. By prioritising workshop air quality during the festive period, you can start the new year safe, productive, and fully compliant.

Alt text: Workshop air quality inspection during festive shutdown

Reduced Production Pressure

During the festive period, most workshops experience fewer active jobs. This reduction in day-to-day operations makes it easier to schedule inspections and maintenance without disrupting output.

Lower Staffing Levels

With some staff on leave for the holidays, coordinating maintenance becomes simpler. Fewer people on-site reduces interruptions and allows the team conducting checks to work efficiently. This period also provides an ideal opportunity to perform thorough inspections of ventilation systems, equipment, and workspaces without affecting day-to-day operations.

By addressing maintenance now, businesses can identify and fix potential issues before production ramps up, minimising the risk of downtime or safety hazards. Additionally, conducting maintenance during quieter periods ensures that when the full team returns, the workshop is fully optimised, safe, and ready for a productive start to the new year.

Planned Shutdowns

Many workshops have already scheduled partial or full shutdowns over Christmas and the New Year. This planned downtime is the perfect opportunity to take systems offline safely and perform thorough maintenance. With production paused, maintenance teams can conduct detailed inspections, clean hard-to-reach areas, and test system efficiency without interrupting operations. Taking advantage of this window helps prevent unexpected breakdowns, ensures equipment reliability, and sets the stage for a smooth, productive start to the new year.

Year-End Compliance

Completing LEV inspections and air quality checks before the start of the new year ensures that your workshop is fully compliant with COSHH regulations and safety standards from day one. It also allows any necessary repairs, upgrades, or adjustments to be carried out without disrupting normal operations. Early inspections help prevent potential safety risks, reduce the likelihood of regulatory non-compliance, and maintain a consistently healthy working environment.

Hidden Build-Up from the Year

Throughout the year, your workshop’s LEV systems work hard to capture welding fumes, grinding dust, paint overspray, wood dust, and other airborne contaminants. Over time, this can lead to:

Filters becoming clogged

Dust and debris are accumulating in the ductwork

Hoods and extraction arms are being knocked out of position

Gradual drops in performance that go unnoticed during daily operations

By December, many systems are overdue for a proper inspection and service. This hidden build-up can reduce airflow, compromise workshop air quality, and even pose safety risks if not addressed. Performing maintenance during the festive shutdown ensures systems are fully operational for the year ahead.

Improved Safety and Efficiency

Performing maintenance during these months reduces the risk of poor air quality-related hazards, such as fire or respiratory issues, and ensures that equipment operates at peak efficiency for the year ahead.

Foundation for a Productive Year

Addressing workshop air quality at this time sets the tone for a healthy, safe, and productive start to the new year, protecting staff, equipment, and overall operational efficiency. Ensuring clean, well-ventilated air reduces the risk of respiratory issues and fatigue, keeping your team alert and focused. It also helps prevent dust and airborne contaminants from settling on machinery and work surfaces, prolonging the lifespan of equipment and maintaining consistent product quality. By prioritising air quality early, businesses demonstrate a proactive commitment to safety and operational excellence, creating a positive work environment that supports both employee wellbeing and long-term performance.

Alt text: Engineers checking workshop air quality in December and January

Key Checks to Schedule During Christmas and New Year

To maintain optimal workshop air quality, schedule these critical tasks during your festive shutdown:

COSHH and LEV Examination and Testing

Ensure your LEV systems are examined and tested in line with COSHH requirements (at least every 14 months). December and January are ideal months to complete these inspections, ensuring full compliance for the new year.

Filter and Component Replacement

Replace worn filters, seals, and other consumable parts. Using genuine spare parts helps maintain performance and protects your investment in the system.

Cleaning and Ductwork Inspection

Remove dust and debris from ducting, hoods, and extraction points. Clean ductwork improves airflow, reduces fire risks, and enhances overall workshop air quality.

Performance Checks and Adjustments

Verify that extraction arms, hoods, and capture points are correctly positioned and delivering the right airflow at the point of use. Even minor misalignments can significantly reduce workshop air quality.

How Workplace Safety Management Can Help

At Workplace Safety Management, we support workshops and small engineering businesses across the UK with:

Planned festive shutdown maintenance for LEV systems

Replacement and upgrade of older or underperforming equipment

Supply of spare parts to keep systems reliable

COSHH-compliant LEV testing and documentation

Advice on improving workshop air quality for the year ahead

We understand that downtime is precious. That’s why we schedule our work around your shutdown dates, ensuring everything is ready for a safe, compliant, and productive start to the new year.

Making Clean Air Part of Your New Year's Plan

As you set targets for the year ahead and higher output, new contracts, and better efficiency and don’t forget the foundation that supports it all: a safe, healthy working environment. Using the quieter weeks around Christmas and New Year to service, test, and, if necessary, upgrade your LEV systems is an investment in your team, your equipment, and long-term productivity. High-quality workshop air quality improves performance, reduces sick days, and ensures compliance with safety regulations.

Conclusion: Start the Year with Cleaner Air

Investing in workshop air quality during the festive shutdown sets the tone for a safe, productive, and efficient year. By prioritising LEV system maintenance, filter replacements, cleaning, and testing in December and January, you protect your team, improve operational efficiency, and ensure full compliance with safety regulations. Taking the time now also reduces the risk of unexpected downtime, costly repairs, and health-related issues later in the year. Clean, well-maintained air systems not only safeguard your workforce but also enhance equipment longevity, maintain consistent performance, and create a more comfortable working environment for everyone on site.

Call Workplace Safety Management or book online to secure your slot before the festive period ends. Your team and your productivity deserve it.

FAQs

1. Why focus on workshop air quality in December and January?

These months are ideal due to quieter operations, planned shutdowns, and easier maintenance scheduling.

2. What maintenance should be done for workshop air quality?

LEV system checks, filter replacements, duct cleaning, and performance adjustments.

3. How often should LEV systems be tested?

At least every 14 months, or during scheduled shutdowns for optimal air quality.

4. What are the benefits of checking air quality during the festive period?

Improved safety, compliance, equipment efficiency, and a healthier working environment.

5. Can workshop air quality impact productivity?

Yes, poor air quality can reduce efficiency, increase health risks, and cause equipment issues.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Workplace Safety Management Ltd

Unit 1 Garden Court

Gee Road

Coalville

Leicestershire

LE67 4NB

Email: [email protected]

COMPANY INFO

CUSTOMER INFO

2025 Workplace Safety Management & Products