Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

Your Partner in Workplace Safety & Compliance

At Workplace Safety Management, we don’t just supply products and services — we deliver peace of mind.

Our blog is here to showcase expert insights, real-world case studies, and the latest innovations in air quality, dust and fume extraction, and LEV compliance.

Whether you manage a busy workshop, factory, or commercial site, you’ll find practical advice and proven solutions to keep your workforce safe, your operations efficient, and your business fully compliant.

How Can Investing in Industrial Air Quality Solutions Upgrade Your Manufacturing Productivity Overnight?

In today’s manufacturing world, every hour your machines run and every healthy worker you have adds directly to your profits. While many facility managers focus on supply chain logistics, a clandestine factor often dictates the rhythm of the shop floor: atmospheric integrity. By integrating advanced Industrial Air Quality Solutions, forward-thinking enterprises are discovering that the air we breathe is a fundamental driver of the Manufacturing Advantage.

The Invisible Catalyst for Operational Excellence

Manufacturing processes by their very nature liberate a complex array of dust, hazardous fumes, and volatile vapours. Over time, these airborne contaminants accumulate, creating a stagnant environment that compromises the biological health of your team and the mechanical health of your hardware. Implementing comprehensive Industrial Air Quality Solutions is the only definitive method to intercept these hazards before they erode your bottom line.

Image Alt Text: A pristine UK manufacturing facility utilising bespoke Industrial Air Quality Solutions to protect technicians and high-precision machinery.

Why Air Quality Matters in the Manufacturing Landscape

The presence of pollutants is often an unavoidable byproduct of production, yet their management is a strategic choice. When a facility neglects its ambient environment, the repercussions manifest across four critical areas of the business. Through consistent Local Exhaust Ventilation (LEV) system maintenance, these risks are mitigated, paving the way for sustainable manufacturing productivity improvements.

1. Minimising Disruptive Sick Days

The most valuable asset in any production line is a reliable workforce. When air quality is compromised, staff are significantly more susceptible to respiratory issues, persistent headaches, and chronic fatigue. By prioritising Industrial Air Quality Solutions, you ensure fewer absences and maintain a robust, dependable team that is ready to meet daily targets.

2. Sharpening Cognitive Focus and Precision

Micro-irritants in the air are not merely health hazards; they are distractions. Physical discomfort leads to a decline in concentration, which inevitably results in human error. Clean air, facilitated by Industrial Air Quality Solutions, allows your team to stay sharp, focused, and exceptionally efficient during demanding shifts.

3. Optimising Machinery Performance and Longevity

Dust and particulates are the sworn enemies of precision engineering. These contaminants infiltrate sensitive electronics and clog cooling vents, leading to overheating and catastrophic breakdowns. Regular LEV system maintenance prevents this build-up, ensuring your machinery remains operational and reducing the exorbitant costs associated with unplanned downtime.

4. Securing Higher Product Quality

In sectors where precision is paramount, airborne particles can settle on products, leading to defects, contamination, or the need for expensive rework. Utilising professional Industrial Air Quality Solutions guarantees that your output meets the most stringent quality standards, protecting your reputation for excellence.

Image Alt Text: A modern industrial workspace demonstrating the clear benefits of Industrial Air Quality Solutions through enhanced visibility and cleanliness.

The Strategic Power of LEV Systems

Local Exhaust Ventilation (LEV) systems are engineered to capture contaminants at the point of origin, preventing them from ever reaching the breathing zone of your staff. However, the efficacy of these systems relies entirely on professional oversight and consistent LEV maintenance.

How Workplace Safety Management Supports Your Vision

To achieve genuine manufacturing productivity improvements, a comprehensive approach to safety management is required. This includes:

Bespoke LEV Design and Installation: Modifying extraction systems to your specific floor layout and machinery.

Preventative LEV System Maintenance: Ensuring components are replaced before they fail, maintaining peak extraction efficiency.

COSHH-Compliant Testing: Providing the rigorous documentation and testing required to meet UK legal standards.

Air Quality Monitoring: Continuous assessment to drive ongoing manufacturing productivity improvements and safety.

To further understand the statutory requirements for your facility, you can consult the HSE Guidelines on Controlling Airborne Contaminants. For a modified audit of your extraction efficiency to ensure your facility is performing at its zenith.

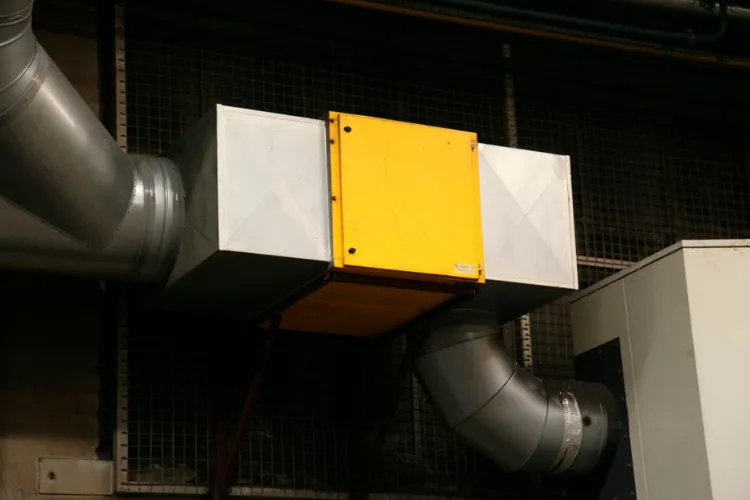

Image Alt Text: A specialist engineer conducting LEV system maintenance to ensure the facility achieves maximum manufacturing productivity improvements.

Final Thoughts

Make 2026 Your Most Productive Year Yet

Do not allow invisible hazards to act as a bottleneck for your business. Investing in Industrial Air Quality Solutions today is a proactive commitment to your team’s health, your machinery’s reliability, and your output’s consistency. By focusing on LEV system maintenance, you remove the barriers to growth and establish a foundation for long-term success.

The economic reality is clear: manufacturing productivity improvements are born from a clean, safe, and optimised environment. As we navigate the challenges of 2026, ensure your facility stands out as a beacon of operational excellence.

Optimise your environment and protect your bottom line with Workplace Safety Management’s industry-leading Industrial Air Quality Solutions.

Secure Your Competitive Edge.

[Consult with Workplace Safety Management for a Comprehensive Site Audit Today]

Frequently Asked Questions (FAQs)

1. Can Industrial Air Quality Solutions Really Reduce Our Annual Absenteeism Rates?

Absolutely. Respiratory irritation and fatigue caused by poor air are leading contributors to short-term sick leave in the manufacturing sector. By removing toxins at the source, you create a healthier environment that naturally reduces the frequency of staff illness and improves overall workforce morale.

2. How Often Should We Schedule LEV System Maintenance to Ensure Compliance?

Under UK COSHH regulations, most LEV systems require a formal examination and test at least once every 14 months. However, for high-intensity environments, more frequent LEV system maintenance is recommended to prevent particulate build-up and ensure the system continues to deliver maximum manufacturing productivity improvements.

3. Will Improving Air Quality Actually Extend the Lifespan of Our Machinery?

Yes. Microscopic dust and metal shavings are highly abrasive and conductive. When these particles settle on sensitive circuitry or moving mechanical parts, they cause premature wear and electrical faults. Maintaining clean air is a form of preventative maintenance for your hardware.

4. What Is the Primary Difference Between General Ventilation and LEV?

General ventilation dilutes the air in the entire building, whereas LEV acts as a targeted Industrial Air Quality Solution. It captures dust and fumes right where they are created, preventing them from spreading throughout the factory, which is far more effective for protecting workers and products.

5. How Do These Improvements Directly Impact Our Bottom Line?

The ROI of Industrial Air Quality Solutions is found in the "Manufacturing Advantage": reduced downtime from machine failure, lower costs associated with product rework, and a significant decrease in the hidden costs of staff turnover and sick pay. Clean air is an investment in your facility's long-term profitability.

How Can Investing in Industrial Air Quality Solutions Upgrade Your Manufacturing Productivity Overnight?

In today’s manufacturing world, every hour your machines run and every healthy worker you have adds directly to your profits. While many facility managers focus on supply chain logistics, a clandestine factor often dictates the rhythm of the shop floor: atmospheric integrity. By integrating advanced Industrial Air Quality Solutions, forward-thinking enterprises are discovering that the air we breathe is a fundamental driver of the Manufacturing Advantage.

The Invisible Catalyst for Operational Excellence

Manufacturing processes by their very nature liberate a complex array of dust, hazardous fumes, and volatile vapours. Over time, these airborne contaminants accumulate, creating a stagnant environment that compromises the biological health of your team and the mechanical health of your hardware. Implementing comprehensive Industrial Air Quality Solutions is the only definitive method to intercept these hazards before they erode your bottom line.

Image Alt Text: A pristine UK manufacturing facility utilising bespoke Industrial Air Quality Solutions to protect technicians and high-precision machinery.

Why Air Quality Matters in the Manufacturing Landscape

The presence of pollutants is often an unavoidable byproduct of production, yet their management is a strategic choice. When a facility neglects its ambient environment, the repercussions manifest across four critical areas of the business. Through consistent Local Exhaust Ventilation (LEV) system maintenance, these risks are mitigated, paving the way for sustainable manufacturing productivity improvements.

1. Minimising Disruptive Sick Days

The most valuable asset in any production line is a reliable workforce. When air quality is compromised, staff are significantly more susceptible to respiratory issues, persistent headaches, and chronic fatigue. By prioritising Industrial Air Quality Solutions, you ensure fewer absences and maintain a robust, dependable team that is ready to meet daily targets.

2. Sharpening Cognitive Focus and Precision

Micro-irritants in the air are not merely health hazards; they are distractions. Physical discomfort leads to a decline in concentration, which inevitably results in human error. Clean air, facilitated by Industrial Air Quality Solutions, allows your team to stay sharp, focused, and exceptionally efficient during demanding shifts.

3. Optimising Machinery Performance and Longevity

Dust and particulates are the sworn enemies of precision engineering. These contaminants infiltrate sensitive electronics and clog cooling vents, leading to overheating and catastrophic breakdowns. Regular LEV system maintenance prevents this build-up, ensuring your machinery remains operational and reducing the exorbitant costs associated with unplanned downtime.

4. Securing Higher Product Quality

In sectors where precision is paramount, airborne particles can settle on products, leading to defects, contamination, or the need for expensive rework. Utilising professional Industrial Air Quality Solutions guarantees that your output meets the most stringent quality standards, protecting your reputation for excellence.

Image Alt Text: A modern industrial workspace demonstrating the clear benefits of Industrial Air Quality Solutions through enhanced visibility and cleanliness.

The Strategic Power of LEV Systems

Local Exhaust Ventilation (LEV) systems are engineered to capture contaminants at the point of origin, preventing them from ever reaching the breathing zone of your staff. However, the efficacy of these systems relies entirely on professional oversight and consistent LEV maintenance.

How Workplace Safety Management Supports Your Vision

To achieve genuine manufacturing productivity improvements, a comprehensive approach to safety management is required. This includes:

Bespoke LEV Design and Installation: Modifying extraction systems to your specific floor layout and machinery.

Preventative LEV System Maintenance: Ensuring components are replaced before they fail, maintaining peak extraction efficiency.

COSHH-Compliant Testing: Providing the rigorous documentation and testing required to meet UK legal standards.

Air Quality Monitoring: Continuous assessment to drive ongoing manufacturing productivity improvements and safety.

To further understand the statutory requirements for your facility, you can consult the HSE Guidelines on Controlling Airborne Contaminants. For a modified audit of your extraction efficiency to ensure your facility is performing at its zenith.

Image Alt Text: A specialist engineer conducting LEV system maintenance to ensure the facility achieves maximum manufacturing productivity improvements.

Final Thoughts

Make 2026 Your Most Productive Year Yet

Do not allow invisible hazards to act as a bottleneck for your business. Investing in Industrial Air Quality Solutions today is a proactive commitment to your team’s health, your machinery’s reliability, and your output’s consistency. By focusing on LEV system maintenance, you remove the barriers to growth and establish a foundation for long-term success.

The economic reality is clear: manufacturing productivity improvements are born from a clean, safe, and optimised environment. As we navigate the challenges of 2026, ensure your facility stands out as a beacon of operational excellence.

Optimise your environment and protect your bottom line with Workplace Safety Management’s industry-leading Industrial Air Quality Solutions.

Secure Your Competitive Edge.

[Consult with Workplace Safety Management for a Comprehensive Site Audit Today]

Frequently Asked Questions (FAQs)

1. Can Industrial Air Quality Solutions Really Reduce Our Annual Absenteeism Rates?

Absolutely. Respiratory irritation and fatigue caused by poor air are leading contributors to short-term sick leave in the manufacturing sector. By removing toxins at the source, you create a healthier environment that naturally reduces the frequency of staff illness and improves overall workforce morale.

2. How Often Should We Schedule LEV System Maintenance to Ensure Compliance?

Under UK COSHH regulations, most LEV systems require a formal examination and test at least once every 14 months. However, for high-intensity environments, more frequent LEV system maintenance is recommended to prevent particulate build-up and ensure the system continues to deliver maximum manufacturing productivity improvements.

3. Will Improving Air Quality Actually Extend the Lifespan of Our Machinery?

Yes. Microscopic dust and metal shavings are highly abrasive and conductive. When these particles settle on sensitive circuitry or moving mechanical parts, they cause premature wear and electrical faults. Maintaining clean air is a form of preventative maintenance for your hardware.

4. What Is the Primary Difference Between General Ventilation and LEV?

General ventilation dilutes the air in the entire building, whereas LEV acts as a targeted Industrial Air Quality Solution. It captures dust and fumes right where they are created, preventing them from spreading throughout the factory, which is far more effective for protecting workers and products.

5. How Do These Improvements Directly Impact Our Bottom Line?

The ROI of Industrial Air Quality Solutions is found in the "Manufacturing Advantage": reduced downtime from machine failure, lower costs associated with product rework, and a significant decrease in the hidden costs of staff turnover and sick pay. Clean air is an investment in your facility's long-term profitability.

Talk to our Team today about your ventilation requirements

Talk to our Team today about your ventilation requirements

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Sign up to our Mailing List

And be the first to find out about all our latest news and special offers.

Workplace Safety Management Ltd

Unit 1 Garden Court

Gee Road

Coalville

Leicestershire

LE67 4NB

Email: [email protected]

COMPANY INFO

CUSTOMER INFO

2025 Workplace Safety Management & Products